TechDry Concrete Blockwork Island Block Pavers

It should be covered with a thick coat of whitewash or crude oil to ensure free movement of the slab. 6. Fixtures and Fittings in Concrete Block Masonry. The fixtures, fittings, etc. in the concrete block masonry shall be built into the masonry in cement and coarse sand mortar 1:3 while laying the blocks.

Reinforced Concrete Block Walls Island Block & Paving

Typically, concrete masonry units have nominal face dimensions of 8 in. (203 mm) by 16 in. (406 mm), available in nominal thicknesses of 4, 6, 8, 10, 12, 14, and 16 in. (102, 152, 203, 254, 305, 356, and 406 mm). Nominal dimensions refer to the module size for planning bond patterns and modular layout with respect to door and window openings.

CONCRETE BLOCK WALLS The New Zealand's First Passive House

Block walls are structures containing standard concrete blocks that can take on various shapes and sizes. The production of cast-in-place (CIP) concrete walls involves casting concrete and a mix of aggregates into a mold at the worksite. While both types are useful for commercial and residential applications, they each have unique.

Concrete, Blockwork and a Love for the Landscape Shape Bare House Cinder block house, Concrete

Building Walls With Concrete Block Michael Langford / Getty Images By Juan Rodriguez Updated on 08/08/19 The residential and commercial construction industries make wide use of a form of concrete building material known officially as a concrete masonry unit (CMU).

Proper Installation of Block Wall or Blockwork YouTube

Guidance on a range of different wall types: crosswall, insulated concrete formwork, twin wall, tunnel form, thin-joint blockwork and tilt-up construction. Blockwork.. Tilt-up construction involves site-casting the concrete walls of a building on its floor slab or on a separate casting bed and then tilting and lifting them into position by.

Commercial Grey Masonry Firth Concrete Blocks

PROS Concrete blocks are great for foundations and basement walls because they are stronger than poured concrete when properly constructed and erected. To configure and secure the blocks, no formwork is necessary, as is the case with poured concrete foundations.

V&A's Home Build Groundwork Part 3 Blockwork foundations

Types of marine concrete structures. P.E. Smith, in Marine Concrete Structures, 2016 2.1.1.1 Blockwork walls. Blockwork walls are typically constructed in wet sites, and the underwater section is constructed from mass (plain) concrete blocks with an in-situ concrete cap for the upper section of the structure. The precast blocks are typically founded on a stone bed and terminate in the tidal zone.

concrete blockwork MS Build

With the exception of ICF (insulated concrete formwork), blockwork is typically insulated by means of a creating a cavity, where a double skin of blocks (usually one of brickwork) sandwiches insulation. Due to recent changes to the Building Regulations, this cavity probably needs to be at least 125mm wide.

Concrete, Blockwork and a Love for the Landscape Shape Bare House

The absolute necessity for "Clean-out blocks" to be documented on structural drawings for the bottom course of all core-filled, reinforced concrete block walls. A highlighted "Hold Point" note should included on the structural drawing that "The clean-out cavity is inspected by the structural engineer, to ensure it is clear of mortar.

Concrete Block Retaining Wall Construction

Concrete masonry walls are often used for their ability to isolate and dissipate noise. Concrete masonry offers excellent noise control in two ways. First, it effectively blocks airborne sound transmission over a wide range of frequencies. Second, concrete masonry effectively absorbs noise, thereby diminishing noise intensity.

Blockwork G&B Construction

Concrete masonry is a generic term covering many building systems that incorporate bricks and blocks of many different shapes and sizes, colours and textures, strengths and other mechanical properties. Concrete masonry units, for use in walls, fall into two broad categories - concrete bricks and hollow concrete blocks.

High density concrete blockwork retaining wall. Blank outdoor wall, solid wall, of solid

How to Build a Concrete Block Wall: Building a concrete block wall (with concrete masonry units, core-fill grout and mortar or mason mix) is one of the more involved building projects.

Method Statement for Masonry Block Work Work Procedure

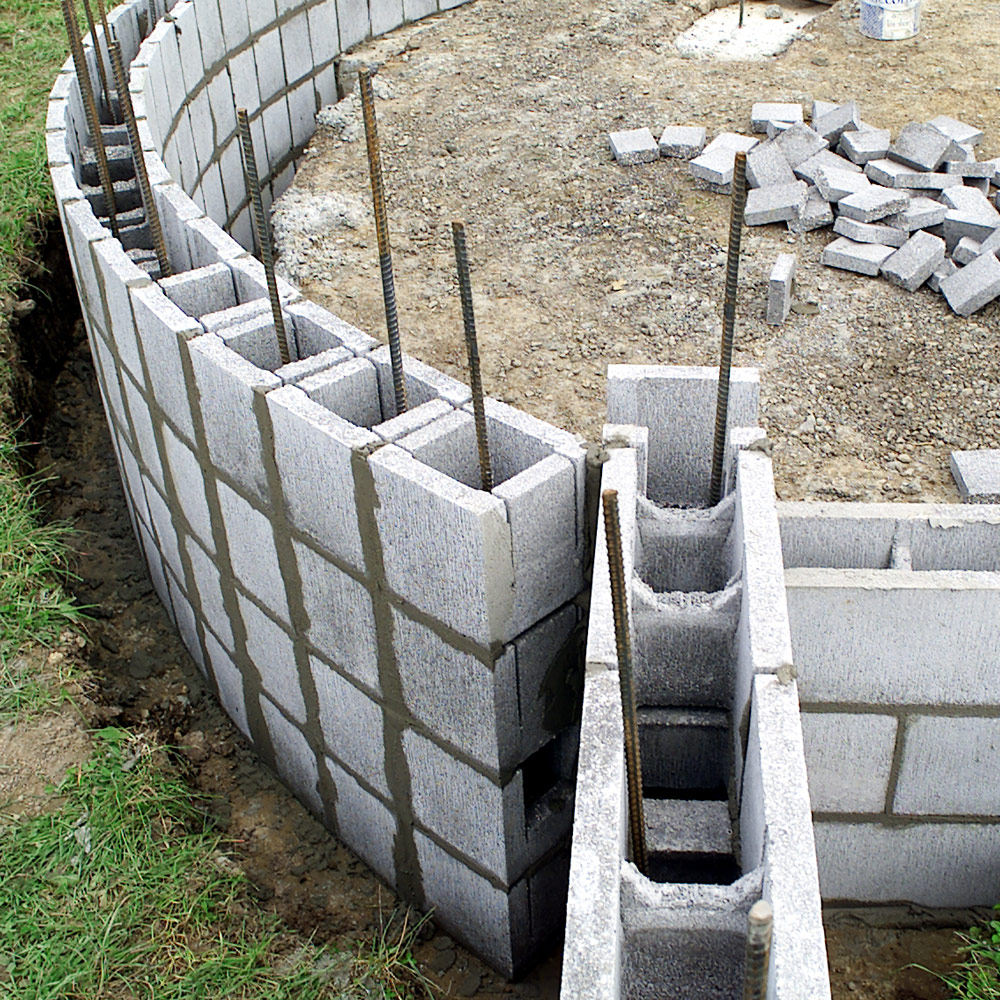

Circular concrete block wall system plan view. Running Bond around outside (from outside start of first (or any) stretcher, to end of each block) You can easily combine this Circular Wall System with the Gable Cutting System to build curved / circular raking walls. Neither system requires a string line, so they combine easily.

AM 10SERIES OPTION2 PP2 Brick exterior house, Concrete block walls, Concrete blocks

PRODUCT GUIDE Masonry Design Guide Masonry Blocks & Bricks Victoria Book 2 Product Disclaimer: Concrete Blocks, Bricks, Pavers and Retaining Wall products supplied by National Masonry are manufactured using raw materials that inherently vary in nature.

Concrete Building Blocks in Melbourne Island Block & Paving

Blockwork. Concrete blocks are a cost-effective, and tried and tested means of providing load-bearing and non-load-bearing walls with many other performance and sustainability benefits. There is a well-established supply chain for concrete blocks in the UK, providing a readily-available source for construction.

How to Construct Concrete Block Masonry? The Constructor

Typically hidden behind plasterboard, blockwork is a common form of masonry construction that uses chunky concrete blocks to create load-bearing or non-load-bearing walls.